Rubber mixing process

Kneading means in order to improve the physical and mechanical properties of rubber products, improve the molding process, reduce production costs, the need for the various raw rubber compounding agents in the rubber or plastic, such as fillers, reinforcing agents, accelerators, vulcanizing agents, antioxidant, scorch like, these ingredients as a solid, liquid and other materials will be added various ingredients evenly dispersed, to ensure uniform property of rubber. So the mixing machine so that the various ingredients uniformly dispersed in raw rubber or plastic mixing of the process called mixing, kneading made by mixing rubber compounds called.

Kneading is through the mechanical action of raw rubber or plastic, rubber and various ingredients uniformly mixing process. Poor mixing, plastic materials will be a variety of problems, such as scorch, blooming, so that rolling, extrusion, coating, curing and other processes normally difficult and result in decreased product performance.

Mixing process consists of four stages: mixing, dispersing, mixing, plasticizing. Raw rubber or plastic rubber shearing and stretching role in mixing machine to produce flow and fracture, broken, full contact with the ingredients to mix. This process is called wetting phase or eat pink stage. After the ingredients into the rubber under the action of mechanical forces, it is further broken into micro-sized fine particles, while increasing the contact surface area and further enhance the uniformity of mixing. So called microscopically dispersed. Various compounding agents in raw rubber or plastic mixing evenly distributed process. The so-called mixing, compounding agents refer only to increase the uniformity of the rubber compound, without changing its particle size. Therefore, this process is also known as macro-dispersion or simple mixing. Rubber molecular mechanical force - under the chemical action continues breaking, the viscosity decreased, to achieve uniform mixing. These processes are not isolated, but is performed simultaneously.

Usually the process mix prepared as follows:

→ complexing agent added processing raw rubber and compounding ingredients weighing → → Quality Inspection

Folding edit this paragraph carbon black dispersion process

Carbon black dispersed in a plastic or rubber raw rubber process, rubber seep between the first carbon black agglomerates to form a high density of carbon black - rubber aggregation lumps are dispersed in raw rubber without carbon black rubber or plastic then the carbon black - rubber agglomerates in large aggregates sufficient physical shearing or tensile force is rubbed open, mass decreases gradually mix until fully dispersed. Carbon black - rubber aggregates in clumps, with the collective carbon black formation, its internal cohesion there is a physical adsorption, the clumps can only suffer more than the physical adsorption of cohesive physical shear or tensile force twist open. Since the required raw rubber or plastic mixing shear deformation or tensile force about its viscosity to achieve overcome physical cohesion carbon black agglomerates to twist open, raw rubber or plastic mixing requires a certain viscosity. With the development of decentralized process, raw rubber or plastic compound containing carbon black is gradually reduced compound viscosity decreased. Carbon black dispersion and the number of fine particles increases, between black and green rubber or plastic mixing increases the contact area between the elastic rubber material recovery value increases when this value does not increase, indicating that the end of the dispersion process.

Wetting and dispersing performance folding Edit this paragraph complexing agent

Granular powder dispersed in the degree of difficulty with their surface properties of rubber related. According to their surface properties can basically be divided into two categories: one is hydrophilic, such as carbonates, clay, zinc oxide, lithopone, silica, magnesium oxide, and other inorganic alkali, etc; the other class is hydrophobic, such as various [[carbon black]] and the like. The surface properties of the former with different raw rubber, which can not easily be wet, which is similar to the surface properties of raw rubber, easily wetted. In order to improve the degree of dispersion of the ingredients, an effective way is to add a surfactant, the surfactant is mostly an organic compound containing -OH, -NH2, -COOH, -NO2, -NO, -SH and other polar groups, in addition, they also contain the molecular structure of a non-polar benzene ring or a long chain hydrocarbon group having hydrophobicity. Thus surfactants act as an intermediary between the rubber compounding agents and improve the mixing effect, but it can also stabilizing agent particles dispersed with the state of dispersion in the rubber, thereby enhancing the stability of the mix.

Folding edit this paragraph rubber compounding process

Rubber mixing process with the agent in the raw rubber mixing uniformly dispersed over its very nature

Kneading

Cheng, granular ingredients were dispersed phase, raw rubber in a continuous phase. In the mixing process, the rubber molecular structure, molecular weight and its distribution, aggregation state complexing agent were changed. By mixing, rubber and compounding agents played a role in physics and chemistry, the formation of a new structure. Mix is a complex structure having a dispersion characteristic. Due to the high viscosity of raw rubber, in order to penetrate the raw rubber compounding agents and uniformly mixed and dispersed therein, must resort to strong mechanical shear mixing machine. Mixing process used by mixing machine type. Mixing machine mainly open and closed categories. Newer mixer is a screw-type transfer device, save energy and floor space, can reduce labor intensity and facilitates continuous production.

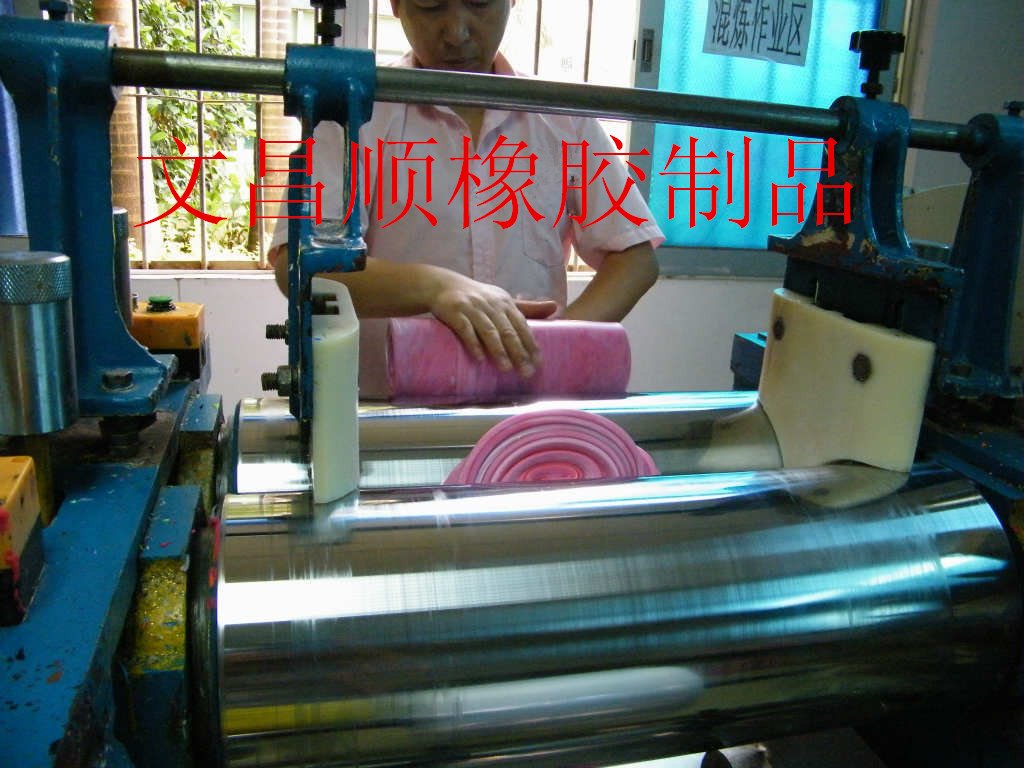

Folding open-roll mixing process

Rubber open mixing machine (see pictures) two rotating roll gap, repeatedly subjected to shearing action by manual control. It includes three stages: ① heating raw rubber. Upcoming been masticated raw rubber in the machine again re-refining, heated and softened, and added other polymer blends. ② plus ingredients. Usually before adding softener, stearic acid, and then adding powder such as carbon black (carbon black, and some can also be pre-mixed into the raw rubber first single masterbatch). In the last general mixing of sulfur, or after the rubber at park, at the time of the second re-refining added. ③ mixing uniformity and the bottom sheet. When all the ingredients added, should continue to turn refining, mixing evenly, then remove the film.

Open mill mixing into packets roll, eating pink, turning three refining stages

① bag roll-up roller is open mill mixing premise. Kneading raw rubber on the open mill rolls have four states. Zone 1, Zone 2, Zone 3 and Zone 4.

Visible, should select the appropriate temperature, the kneading raw rubber bag roll in Zone 2. Various rubber glass transition temperature varies, and therefore different packages rubber roller temperature optimum region 2 is different. Natural rubber and SBR wide molecular weight distribution, and therefore suitable for a wide range of temperatures, generally appear only zones 1 and 2, under normal operating temperature, no obvious Zone 3, the package rolls and mixing performance it is good. Molecular weight butadiene rubber, synthetic rubber narrow distribution, suitable temperature range on the narrow, cold pack roller in zone 2, or more, if at 323.5K namely transition to Zone 3, this time even if the roll gap can not be reduced to a minimum Back to zone 2. Thus, a variety of raw rubber or plastic mixing must master operating conditions to select the appropriate temperature, so that in Zone 2 pack roll kneading to prevent the transition to zone 1 or Zone 3, and 4 should be rolling Area.

② After eating pink rubber roller bag should retain an appropriate number of stacking gel in a roll from the top, and then to add the ingredients piled on the plastic. When the complexing agent is added, since the stacking gel by the resistance, folded, corrugated, continued flipping and turnover, with the agent will be brought into the stacking gel corrugated section and roll into the distance, allowing ingredients in a radial cut cut deformation effect occurs not only peripheral to the mixing, but also a mixed bag roll of film to a thickness direction of dispersion. The amount of stacking gel can not be too much or too little, too little complexing agent will only cut people rub the surface after sizing and rubber roll, while mixing in smaller rubber thickness direction (radial) is not easy When the compounding agent into the interior, poor mixing effect; too much can make the excess plastic material in the roll from the top of the inverted roll, pitch and roll can not successfully enter not kneaded.

③ Total refining since the viscosity of the rubber is large, only produce circumferential flow along the direction of rotation of the roller tube during kneading and laminar flow, close to the surface of the roller accounted for one third of the thickness of the film roll package of plastic material can flow generated and become "dead layer", only two-thirds of the active layer, a layer of dead suffered shear has little to with the agent can not enter therein. In addition, the upper part of the roll from the stacking gel will form part of the wedge ´recirculation zone. " Therefore, immediately after eating flour mill to turn the cutting operation, changing the direction of the flow of plastic material, so that dead layer of rubber material constantly being taken to the top of the stacking gel and into the active layer, so that ingredients are fully dispersed and mixed.

Advantages and disadvantages of open mill mixing

The disadvantage is that open mill mixing powder flying large environmental pollution, poor security, labor-intensive, low productivity, production scale is relatively small; the advantage is for kneading or more types of plastic manufacture of special types of plastic, flexibility.

Folding rubber mixer mixing process

Gap size for mixer (see pictures) surface of the rotor and the mixing chamber wall surface, there is a wide range of changes with the rotation of the rotor of the compound exerts strong shearing action. Mixing effect is much greater than the open rubber mixing machine, all kinds of powder ingredients in the mixing chamber and glue mixing without flying out, and automated meter control the mixing process, for example in the mixing process, the temperature of the plastic material the material of the interior volume and power consumption changes in certain laws (see figure).

Kneading mixer

Mixer mixing process for some general mixing method, two-stage mixing method.

Some mixing method

Some mixing method from the feed mixer, mix the backsheet cooling once. And tableting machines generally used in conjunction with, first raw rubber or plastic mixing ingredients in a certain order and put into the mixing chamber of the mixer, mix, latex in tableting on a tablet machine, and rubber temperature reduce, this time adding a low temperature vulcanizing agent and the need to join with the agent, and then by means of plastic or artificial pound pound rubber refining repeatedly pressed to uniform mixing, the mixer and tabletting machine once kneaded to obtain a homogeneous kneaded gel method is called a period of mixing method.

(1) the traditional period of kneading method

The Plastic compounds and various ingredients gradually added in portions, after each feeding, lay down on the top bolt, the degree of pressure as the case may be.

Some traditional kneading method of kneading procedure is generally as follows: rubber (raw rubber, plastic compound, reclaimed rubber, etc.) → acid → accelerators, agents, reinforcing fillers antioxidant → → → softener liquid latex → tabletting machine plus sulfur and speeding accelerator → → cooling showings, parking

(2) sub-paragraph vote glue mixing method

Raw rubber was added in portions to enhance dispersion of carbon black, to improve and enhance the rubber material properties and physical and mechanical properties of vulcanized rubber.

What to do: put 60% to 80% of the raw rubber and compounding agents (except the vulcanizing agent and the super-accelerator), at 70 ~ 120 ℃ temperature kneading, mixing 70 to 80% of the total mixing time, and then the rest raw rubber and put together with the vulcanizing agent and the super-accelerator, and then mixing 1 ~ 2min after row of plastic backsheet.

Two kneading method

Some materials, such as neoprene rubber material, butadiene rubber at the mixer after mixing, tableting machine showings in cool and parked for some time, cooled and viscosity increase after the park, so that when the plastic material in the mixing greater shear or tensile force, making rubber and compounding ingredients and mix more easily broken. Then back to the internal mixer and then compressed on a tablet machine vulcanizing agent, ultra-promoting agent, and uniformly dispersed to obtain a homogeneous mix, this method is called a two-stage mixing method.

(1) mixing the traditional two-stage method

Rough-kneading the first stage with a high speed mixer of high pressure, the rubber and compound mixing made masterbatch, after showings after parked for some time, and then fed into the mixer plus low sulfur and accelerator were kneaded , and then added tableting machine processing film.

(2) sectionally glue two kneading method

The first stage kneading, about 80 percent of the raw rubber fed into a conventional two-stage mixing and kneading the same method to prepare a masterbatch. When the second stage kneading the remaining 20% of the raw rubber into masterbatch kneading, even the rear rubber.

Mixer mixing advantages and disadvantages

Kneading mixer and open mill mixing compared to the high degree of mechanization, low labor intensity, mixing time is short, high production efficiency, reduce the powder flying. But the slow cooling mixer, mixing temperature control difficult, NA temperature-sensitive rubber, latex irregular shape is not fixed.

Folding inverse mix (down mix) refining method

First of all the other ingredients except the sulfur and accelerator all loaded mixer, and then kneaded into raw rubber.

Folding cold mixing process elements

A low temperature batch process method differs from the traditional multi-stage mixing process (high temperature oxidative cleavage, supplemented by mechanical shear to achieve rubber molecular chain rupture) is the biggest feature in the mill and sulfur plus cast, reinforced rubber compound mechanical shearing force, weakening the role of high-temperature oxidative cleavage, the effective time, the greater the shearing of the rubber dispersed rubber molecular chains break and ingredients, the better, so how to improve on the open mill rubber shear is the most critical factor.

Shear rate and shear plastic material is proportional to the shear rate is proportional to the ratio of open mill (machine main roll ratio of 1: 1.07, from 1: 1.143, tablet press roll ratio of 1: 1.09 out sheet 1: 1.143), and the open mill speed is directly proportional to the open mill roll gap. Low-temperature process of Key Factors - roll temperature, roll gap, roll speed low kneading the most important influencing factor is the temperature of mill rolls, because to achieve the so-called low-temperature kneading (ie compounds present in the mill on roll has remained at a low temperature between 70-90 degrees kneading, it must remain open mill roll body temperature between 20-40 degrees, the maximum roll temperature should not exceed 60 degrees, otherwise prone to scorch and Effect of sulfur masterbatch evenly dispersed.

Folding Edit this paragraph preparation before kneading

Preparations include pre-mixing: the raw materials sampling, testing; do not apply with the agent added processing; weighing complexing agent.

Quality inspection of raw materials

Usually examine the content of the main ingredients purity, particle size, moisture content, mechanical impurities, ash and volatile matter content, pH and viscosity of the liquid ingredients. In accordance with the specific type of agent varies. Raw rubber or plastic mixing in addition to test the chemical composition and Mooney viscosity, it should also examine the physical and mechanical properties.

Supplementary processing complexing agent

Supplementary processing ingredients mainly pulverized solid with the agent; drying and screening of powdery complexing agent; preheated low melting ingredients melt and filtration; heating and filtering the liquid complexing agent; and paste masterbatch preparation, etc. .

Smash

Massive or coarse granular ingredients need to go through crushing, grinding or planing process into fine pieces (such as stearic acid, paraffin, asphalt and pine oil, etc.) can be used, so that the dispersion in the rubber compound. Grinding equipment commonly used in disk-mill, a ball mill, a jet mill, hammer crusher, flaker and the like.

dry

When the complexing agent contains more water or low volatile matter impurities such ingredients readily agglomerate, screening not only difficult, but also in kneaded easily be pressed into large aggregates and difficult to disperse such material or semi-finished rubber vulcanization internal prone to bubbles, resulting in waste and defective. It is necessary to remove or reduce low volatile matter where moisture or impurities. Drying device with a drying chamber, vacuum oven, spiral continuous drying machines.

filter

When the particle size and particle size complexing agent Buda points less than the standard, or which contains mechanical impurities, such as sand, wood chips, a small metal device with the agent itself and large particles and agglomerates and the like. Because of these impurities mixed in, it will reduce the physical and mechanical properties of vulcanized rubber, easy to damage the device. Commonly used equipment shaker, drum sieve, spiral sieve machines.

Melting and filtering and heating

Low melting solid softener must first be heated to melt, after reaching dehydration and reduce the viscosity of the role, and then hot [[filter]] to remove one of a variety of mechanical impurities. While [[viscosity]] too high a liquid softener should be heated dehydration and reduce its viscosity, for filtered hot to remove impurities.

Preparation of ointments and masterbatches

Some of the individual ingredients (even a short time is difficult kneading, generates heat, large energy consumption) to a relatively large proportion of prior individual blend components is relatively simple, the high concentration masterbatch and raw rubber or plastic compound glue. Certain ingredients, such as accelerators, zinc oxide, sulfur, etc., in advance with a liquid softener blend paste mixture so readily dispersible ingredients, reduce dust with powdered agents and improve working conditions.

Weighing complexing agent

Weighing ingredients is one of the main pre-preparation step for preparing the compound. Weighing accuracy of rubber processing performance and product quality plays an important role. It must be done carefully, do not drain well, accurate. Weighing and feeding complexing agent in two ways: manual and automatic weighing weighing feeding feeding. The former applies to non-technologically small and medium-scale production, which applies to high technical level of mass production.

Kneading can be open mill, mixer and screw continuous mixer. Require manual operation of skilled with open mill mixing time, labor-intensive, and unsafe. With mixer mixing operation safety, labor intensity, is the most common. Kneading requirements with the agent uniformly dispersed in raw rubber to form a colloidal dispersion, so that the vulcanized rubber has the best performance. While the mix of plastic materials also have certain requirements, so that it can meet the requirements of the latter step. And there is a two-stage mixing method. The former is gradually added in the rubber compounding agents. The latter is the first powder filler added softener and the first stage of a crude kneaded compound after cooling and placing certain time, together with the second paragraph of sulfur and accelerator were kneaded.

Rubber (gum) with a variety of ingredients (see rubber compound) in a mixing machine mixing rubber processing technology. To be able to join the powdered ingredients in rubber, raw rubber mastication must first improve its plasticity and liquidity. Mixing process is the basic process of rubber processing, quality ingredients added to the mix after the material of process performance and product quality semi-finished products have a decisive influence.

Prev:NothingNext:Rubber mixing process