CR,,Rubber, rubber, rubber, oil resistant rubber, rubber seal

Appearance is milky white, beige or light brown flakes or lumps is chloroprene (i.e. 2 - chloro - 1,3 - butadiene) as the main raw material of alpha - polymerization generated elastic body. Chloroprene rubber solubility parameters for Delta =9.2~9.41. soluble in toluene, xylene, dichloroethane, ethylene three vanadium, micro soluble in acetone, methyl ethyl ketone, ethyl acetate, cyclohexane, insoluble in hexane, solvent naphtha, but soluble in the mixed solvent composed of appropriate proportion of good solvent and non solvent and non solvent and non solvent and non solvent, in plant oil and mineral oil swelling and dissolution.

Have good physical and mechanical properties, oil resistance, heat resistance, flame resistance, resistance to sunlight, ozone resistance, acid and alkali resistance, resistance to chemical reagents. The disadvantage is cold and poor storage stability. It has high tensile strength, elongation and crystallization of reversible, good adhesion. Aging resistance, heat resistance. Oil resistance, chemical resistance excellent weatherability and corrosion resistance. Ozone aging after ethylene propylene rubber and butyl rubber. The heat resistance and the nitrile rubber, the decomposition temperature of 230~260 DEG C, short-term resistance at 80~100 DEG 120~150 DEG C, can be used for a long time, with a certain flame retardancy. The oil resistance of nitrile rubber. Only the reverse resistance of inorganic acid, alkali and good corrosion resistance. Cold is a bit poor, poor electrical insulation rubber. Poor storage stability, will have a "sulfur" phenomenon, Mooney viscosity increased, rubber hardens. Foreign brands are AD, 30 (USA), A-90 (Japan), 320 (Germany), MA40S (France).

Folding edit this paragraph application

CR122 type chloroprene rubber: belt, conveyor belt, wire and cable, oil resistant rubber hose, rubber sealing material.

CR232 type of chloride butyl rubber: cable sheath, oil resistant rubber hose, rubber seal, adhesive and so on.

CR2441 2442 type of chloride butyl rubber: adhesive production of raw materials for metal, wood, rubber, leather and other materials bonding.

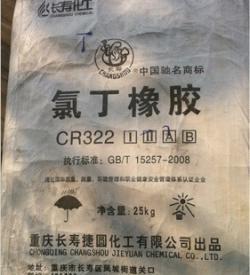

CR321 322 type chloroprene rubber: cable, rubber sheet, ordinary and oil resistant rubber hose, oil resistant rubber boots, air duct, ponchos, tent cloth, conveyor belt, conveyor belt, rubber seals, agricultural capsule air cushion, lifeboat.

Used as the modified acrylate structure adhesive (SGA) toughening agent.

Upstream raw materials: calcium carbide, hydrogen chloride

Downstream products: nylon membrane, chloroprene rubber asphalt waterproof coating, adhesives, adhesive 802, chloroprene rubber adhesive, chloroprene rubber, polychloroprene phenolic adhesive (801), neoprene adhesive mixture 202, Graft Chloroprene rubber adhesive, adhesives, waterproof adhesive, glue, yellow, quick drying adhesive, rubber belt, gear cutting edge with

Folding edit this paragraph production method

Different storage. A chloroprene rubber by emulsion polymerization production, production process for single pot batch polymerization. The polymerization temperature control in 40 to 60 DEG C, the conversion rate is 90%. The polymerization temperature, the final conversion rate is too high or polymerization process into the air (oxygen) will lead to product quality decline. In the production of sulfur - monosulfide (four alkyl amino thionic disulfide) system of regulating molecular weight sulfur - thiuram system the main disadvantage is that the disulfide bond is not stable enough, which is the important one of the reasons. If using thiol adjustable molecular weight, can improve this performance. Chloroprene rubber and synthetic rubber, it do the sulfur vulcanization, but with zinc oxide, magnesium oxide and sulfide.

Research on the folding editing of this paragraph

Analysis of the supply structure of folding 2010-2011

Because of the production of China´s rubber rubber can not meet the actual needs of the country, and therefore need to import every year.

China Chemical Engineering Group with a number of new integration technology, and solve the raw material, the utility consumption is high, the by-product multi, less product variety, quality is poor and unstable, discharge of sewage, exhaust, poorer production safety defects. Compared with the original process, effectively reduces the energy consumption, product variety by several increased to more than 30, so that the copper containing wastewater containing latex wastewater treatment technology is successfully used in the production of the device, an effective solution to the environmental pollution.

Generally used in the production of automotive parts, machinery and industrial products and adhesives, and in the construction, coating fabric, wire / cable and other applications, while in Western Europe and North America, the market is gradually shrinking.

Secondly, due to the relatively high price of the rubber and the temperature rise under the hood, the chloride butyl rubber is gradually replaced by other types of rubber.

The comprehensive performance of the rubber is good, the natural rubber and other synthetic rubber can not match, the rubber in each country´s transportation, construction, light industry and military and other fields have been widely used.

Prev:LSR,Introduction and application of liquid silica gelNext:Nothing