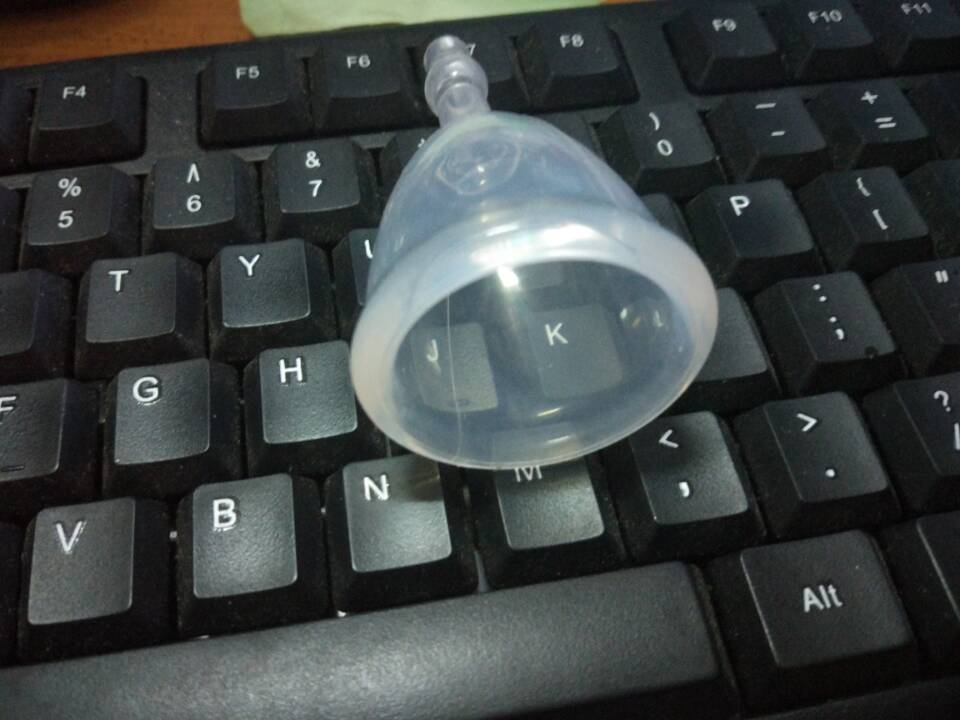

- Silicone female masturbation

- Category:Silicone accessories

- Model:

- Delivery:

- View:1193

Mobile: (+86)13690342007

WeChat: 13690342007

Email: wcs@wcsrubber.com

OnLine:9:00 - 21:00(China Time)

Detail

Silicone products characteristics

High temperature: suitable for the temperature range of -40 to 230 degrees Celsius, can be used in the microwave oven and oven.

Easy to clean: Silicone to produce silicone products used in the water can be washed back to clean, but also in the dishwasher cleaning.

Long life: silicone material chemical properties are stable, the system to make the product, compared with other materials have a longer life.

Soft and comfortable: thanks to the softness of silicone materials, cake mold products feel comfortable, very flexible, no distortion.

Color and diverse: according to customer needs, the deployment of a different beautiful color.

Environmental non-toxic: from raw materials to finished products shipped into the plant do not produce any toxic and hazardous substances.

Electrical insulation: silicone rubber has a high resistivity, and in a wide temperature range and frequency range of its resistance can still be stable. At the same time silica gel for high voltage corona discharge and arc discharge has a good resistance, such as high voltage insulators, TV high pressure hats, electrical parts and so on.

Low-temperature resistance: ordinary rubber minimum operating temperature of the critical point of -20 degrees to -30 degrees, while the silicone rubber in the -60 degrees to -70 degrees still has good flexibility, some special formula of silicone rubber can withstand Very low temperature, such as low-temperature seals and so on.

Conductivity: When adding conductive filler (such as carbon black), silicone rubber will have good electrical conductivity, such as the keyboard conductive contact points, electric components, antistatic components, high voltage cable shielding, medical physiotherapy conductive film.

Weather resistance: ordinary rubber corona discharge generated by the rapid degradation of the role of ozone, and silicone rubber is not affected by ozone, and a long time in the ultraviolet and other climatic conditions, its physical properties are only minor changes, such as outdoor use Sealing materials.

Thermal conductivity: When adding some thermal conductive filler, silicone rubber will have good thermal conductivity, such as heat sinks, thermal sealing gasket, copiers, fax machines, such as heat transfer roller.

Radiation resistance: Containing phenyl-based silicone rubber radiation resistance greatly improved, such as electrical insulation cables, connectors and other nuclear power plants.

classification

Silicone products according to the different molding process can be divided into three categories

Molded silica gel

Molded silicone products are usually through the high-temperature mold in the addition of curing agent after the solid silica gel raw materials through the vulcanization station pressure, high temperature sulfur into solidification molding, molded silicone hardness is usually 30 ° C-70 ° C. Raw materials with color paste in accordance with Pantone color card number transferred out of the color, mold shape determines the shape of molded silicone products, molded silicone products is currently the most widely used in the silicone industry. Silicone keychain, mobile phone sets, silicone kitchen utensils, silicone pads, ice lattice, cake mold, and so on. Mainly used for silicone industry accessories, buttons, silicone gifts, silicone bracelets, silicone watches.

Extrusion silica gel

Extrusion silicone products are usually extruded through the extrusion of silicone molding machine, the general shape of extruded silicone is long, tubular can be cut at will, but the shape of extruded silicone has limitations in the medical equipment, food machinery widely use.

Liquid silica gel

Liquid silicone products are sprayed through silicone injection molding, the product is soft, hardness can reach 10 ° C-40 ° C, because of its soft characteristics, in the simulation of human organs, medical silicone breast pad, and so widely used.

Special products

Special silicone products are based on the chemical properties of silica gel or the addition of some auxiliary materials, special silicone products can also have high temperature (up to 330 degrees), food grade (in full compliance with FDA, LFGB standards), medical grade, , By adding auxiliary raw materials can also have, luminous, negative ions, discoloration, and other characteristics.

use

1, silicone products is the production of copiers, keyboards, electronic dictionaries, remote control, toys, silicone keys, and other indispensable components.

2, can be used to make durable shape of the gasket, the electronic components of the packaging materials, automotive electronics accessories maintenance materials.

3, can be used for the production of electronic components, molded high point pressure of the child.

4, can be used to produce conductive silicone, medical silicone, silicone foam, silicone mold, and so on.

5, for the housing construction and repair, high-speed kilometer joint sealing, bridge sealing and other sealing works.

6, can be used for baby supplies, maternal and child supplies, baby bottles, bottle protection.

7, can be used for kitchen products, kitchenware production and related auxiliary kitchen products

8, can be used for medical equipment accessories, colorless, odorless, non-toxic silicone and other characteristics widely used in the medical industry.

High temperature: suitable for the temperature range of -40 to 230 degrees Celsius, can be used in the microwave oven and oven.

Easy to clean: Silicone to produce silicone products used in the water can be washed back to clean, but also in the dishwasher cleaning.

Long life: silicone material chemical properties are stable, the system to make the product, compared with other materials have a longer life.

Soft and comfortable: thanks to the softness of silicone materials, cake mold products feel comfortable, very flexible, no distortion.

Color and diverse: according to customer needs, the deployment of a different beautiful color.

Environmental non-toxic: from raw materials to finished products shipped into the plant do not produce any toxic and hazardous substances.

Electrical insulation: silicone rubber has a high resistivity, and in a wide temperature range and frequency range of its resistance can still be stable. At the same time silica gel for high voltage corona discharge and arc discharge has a good resistance, such as high voltage insulators, TV high pressure hats, electrical parts and so on.

Low-temperature resistance: ordinary rubber minimum operating temperature of the critical point of -20 degrees to -30 degrees, while the silicone rubber in the -60 degrees to -70 degrees still has good flexibility, some special formula of silicone rubber can withstand Very low temperature, such as low-temperature seals and so on.

Conductivity: When adding conductive filler (such as carbon black), silicone rubber will have good electrical conductivity, such as the keyboard conductive contact points, electric components, antistatic components, high voltage cable shielding, medical physiotherapy conductive film.

Weather resistance: ordinary rubber corona discharge generated by the rapid degradation of the role of ozone, and silicone rubber is not affected by ozone, and a long time in the ultraviolet and other climatic conditions, its physical properties are only minor changes, such as outdoor use Sealing materials.

Thermal conductivity: When adding some thermal conductive filler, silicone rubber will have good thermal conductivity, such as heat sinks, thermal sealing gasket, copiers, fax machines, such as heat transfer roller.

Radiation resistance: Containing phenyl-based silicone rubber radiation resistance greatly improved, such as electrical insulation cables, connectors and other nuclear power plants.

classification

Silicone products according to the different molding process can be divided into three categories

Molded silica gel

Molded silicone products are usually through the high-temperature mold in the addition of curing agent after the solid silica gel raw materials through the vulcanization station pressure, high temperature sulfur into solidification molding, molded silicone hardness is usually 30 ° C-70 ° C. Raw materials with color paste in accordance with Pantone color card number transferred out of the color, mold shape determines the shape of molded silicone products, molded silicone products is currently the most widely used in the silicone industry. Silicone keychain, mobile phone sets, silicone kitchen utensils, silicone pads, ice lattice, cake mold, and so on. Mainly used for silicone industry accessories, buttons, silicone gifts, silicone bracelets, silicone watches.

Extrusion silica gel

Extrusion silicone products are usually extruded through the extrusion of silicone molding machine, the general shape of extruded silicone is long, tubular can be cut at will, but the shape of extruded silicone has limitations in the medical equipment, food machinery widely use.

Liquid silica gel

Liquid silicone products are sprayed through silicone injection molding, the product is soft, hardness can reach 10 ° C-40 ° C, because of its soft characteristics, in the simulation of human organs, medical silicone breast pad, and so widely used.

Special products

Special silicone products are based on the chemical properties of silica gel or the addition of some auxiliary materials, special silicone products can also have high temperature (up to 330 degrees), food grade (in full compliance with FDA, LFGB standards), medical grade, , By adding auxiliary raw materials can also have, luminous, negative ions, discoloration, and other characteristics.

use

1, silicone products is the production of copiers, keyboards, electronic dictionaries, remote control, toys, silicone keys, and other indispensable components.

2, can be used to make durable shape of the gasket, the electronic components of the packaging materials, automotive electronics accessories maintenance materials.

3, can be used for the production of electronic components, molded high point pressure of the child.

4, can be used to produce conductive silicone, medical silicone, silicone foam, silicone mold, and so on.

5, for the housing construction and repair, high-speed kilometer joint sealing, bridge sealing and other sealing works.

6, can be used for baby supplies, maternal and child supplies, baby bottles, bottle protection.

7, can be used for kitchen products, kitchenware production and related auxiliary kitchen products

8, can be used for medical equipment accessories, colorless, odorless, non-toxic silicone and other characteristics widely used in the medical industry.